Need a grant for LED upgrades or

voltage optimisation? (read more)

Need a grant for LED upgrades or

voltage optimisation? (read more)

At Powervolt Team in Olney, we understand the pivotal role that power factor correction plays in enhancing the performance of your electrical systems. Our Power Factor Correction Service in Olney is meticulously designed to provide your business with the necessary tools and expertise to harness the full potential of your energy supply while minimising losses.

Whether your business in Olney relies on electrical machinery or you simply aim to streamline operations, our solutions are bespoke and tailored to meet your unique requirements. Join us on this journey towards heightened energy efficiency and sustainable cost savings, and unlock the power of efficient electrical systems with the Powervolt Team.

For those who need to get up to speed with this useful technology, here's a brief overview of what it's all about:

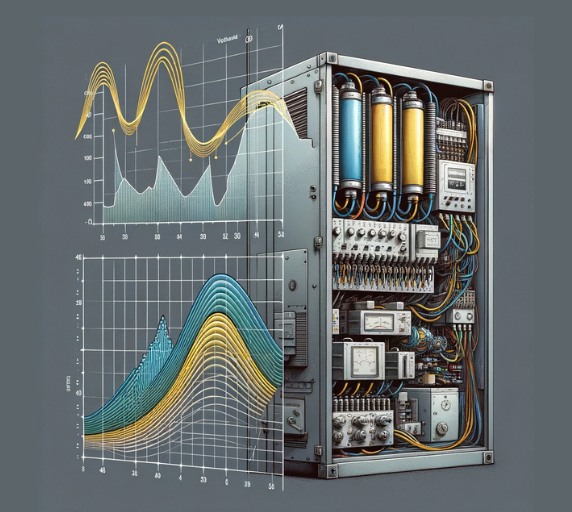

PFC is a technique that enhances the efficiency of electrical systems. It involves adjusting the power factor of a system to bring it closer to unity* (1.0). This correction minimises wasted energy, reduces costs, and optimises electrical power, making it an essential solution for businesses in Olney relying on electrical machinery and equipment. By improving the alignment of voltage and current waveforms, PFC ensures that your electrical system operates at its most efficient, ultimately leading to energy and cost savings.

Power factor correction works well in tandem with voltage optimisation but they are different services to each other we covered in our article “what is the difference between voltage optimisation and power factor correction?”.

*A factor of 1.0 indicates a perfect alignment between the voltage and current waveforms in an electrical system

Powervolt Team is the preferred choice in the UK for energy solutions. Specializing in voltage optimisation, LED lighting, renewable energy, and more, we offer expertise, customized services, and a commitment to sustainability. Choose us for innovative and efficient energy management.

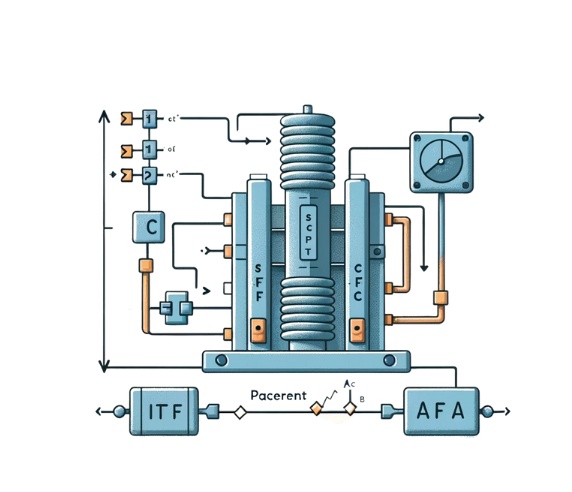

Most PFC equipment is capacitor-based and works to adjust the power factor as close to 1.0 (unity) as possible. Here's a rough idea of how it works:

Powervolt Team is the preferred choice in the UK for energy solutions. Specializing in voltage optimisation, LED lighting, renewable energy, and more, we offer expertise, customized services, and a commitment to sustainability. Choose us for innovative and efficient energy management.

At Powervolt Team, we are dedicated to providing you with the highest standard of power factor correction solutions, tailored to meet your unique needs. With a team of experts well-versed in power factor correction and a comprehensive range of power quality products, we ensure that your electrical systems operate at peak performance. Make the wise choice by choosing the Olney Powervolt Team for your PFC needs and begin your journey towards improved power quality and substantial cost savings.

Power factor correction is important in the UK as it helps in reducing the demand on the electricity supply, leading to more efficient energy use and potentially lower electricity costs for businesses. Additionally, with the UK's focus on reducing carbon emissions, improving energy efficiency through power factor correction contributes to environmental sustainability goals.

UK businesses benefit from power factor correction through reduced electricity bills, as it decreases the amount of reactive power drawn from the grid, thus lowering demand charges. It also helps in reducing the strain on electrical components, potentially extending their lifespan and reducing maintenance costs.

Yes, power factor correction can significantly reduce electricity bills for UK businesses. By improving the power factor, it reduces the amount of reactive power drawn, which can lower demand charges on the electricity bill, particularly for businesses with large, fluctuating power loads.

Power factor correction can indeed improve the lifespan of electrical equipment. By reducing the amount of reactive power in the system, it lessens the stress on electrical components such as motors and transformers, thereby reducing overheating and wear, which can extend the equipment's operational life.