Need a grant for LED upgrades or

voltage optimisation? (read more)

Need a grant for LED upgrades or

voltage optimisation? (read more)

At Powervolt Team, we're passionate about empowering you with knowledge to make informed decisions about electrical solutions.

In this article, we will delve deep into the world of step-down transformers, exploring what they are, their numerous benefits, and how they work, and answering a series of frequently asked questions to provide you with an extensive understanding of these essential electrical devices.

While many people understand that a basic transformer is a handy component used to transfer electric power efficiently between circuits, a step-down transformer is slightly different. In this blog, we've broken the subject down into bite-sized chunks, and some sections may overlap and certain facts are repeated - this is to help you understand the subject better.

So, let's jump in and see what we can learn.

A step-down transformer is a vital electrical device designed to reduce the voltage of an AC power supply while increasing the current. It consists of two coils, the primary coil (typically with more turns) and the secondary coil (usually with fewer turns), which are interconnected by a magnetic core. This ingenious device allows you to 'step down' the voltage for various applications, making it versatile and indispensable in a wide range of electrical systems.

Essentially, it converts a high voltage power supply (HV) with a low current from the primary side to a low voltage (LV) and high current.

They come in all sizes; a substation transformer can be as large as 12 ft in height, whereas low voltage wall adapters can be only a few centimetres across. However, they all essentially do the same job.

For example, power circuits in our homes carry around 230v, but some appliances only need 16v, so a transformer converts high voltage to a usable level. The power supply to our homes is also stepped up and stepped down to reduce power losses from electricity generating stations along the power lines.

Check out: What Is An Uninterruptible Power Supply?

Step-up and step-down transformers are two fundamental types of transformers that serve opposite purposes in electrical systems. Here's a brief description of the key differences between these two types:

Step-Up Transformers:

Delve further: What Is A Step-Up Transformer?

Step-Down Transformers:

In summary, the primary difference lies in their ability to either increase or decrease voltage. Step-up transformers are used to raise voltage for efficient long-distance transmission, while their counterparts are employed to lower voltage to meet the requirements of electrical devices and ensure safety in various applications.

Step-down transformers offer a plethora of benefits, making them crucial components in many electrical systems:

One of the main benefits of a step-down transformer is its ability to maintain a steady voltage supply. This is especially critical for sensitive equipment, preventing voltage fluctuations or excessive voltage that could otherwise lead to damage or malfunction. Voltage stability is essential in industries where precision and consistency are paramount.

Lowering voltage is inherently safer for many applications, reducing the risk of electrical shock and fire hazards. By using these transformers, you can ensure that electrical systems are operating at a voltage level that poses minimal danger to both equipment and individuals.

A step-down transformer is invaluable when it comes to making equipment compatible with different voltage standards. For instance, when dealing with imported appliances designed for a voltage system different from the one in your region, a step-down transformer can bridge the voltage gap, ensuring that your imported devices function flawlessly.

They help optimise energy consumption. By lowering the voltage to match the specific requirements of the connected load, step-down transformers can significantly reduce energy wastage. This can result in substantial cost savings on utility bills, making them an eco-friendly and cost-effective solution.

In regions with unstable or fluctuating power supplies, voltage spikes and surges are common occurrences. A step-down transformer can act as a line of defense against these issues by providing a consistent, manageable voltage to your equipment, protecting it from potential damage due to sudden power fluctuations.

They often have the added benefit of reducing electrical noise. This can be especially important in certain applications where electrical interference could disrupt sensitive equipment, such as in the medical or scientific fields.

By efficiently reducing voltage, step-down transformers can also lead to decreased heat generation in electrical equipment. This can extend the lifespan of devices, reduce maintenance costs, and enhance overall system reliability.

Step-down transformers come in various sizes and configurations, making them suitable for diverse applications. Whether you need a small unit for your home appliances or a robust transformer for industrial machinery, there is a step-down transformer to fit your needs.

Understanding the inner workings of step-down transformer operation can be illuminating. Let's look at the details:

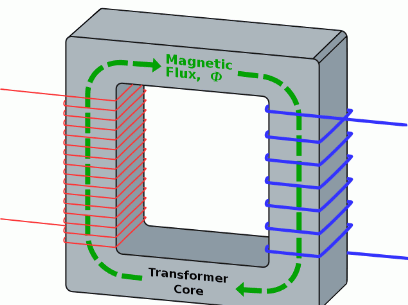

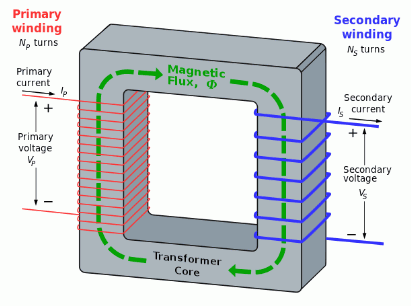

The primary coil, typically with more turns, is connected to the high-voltage source. When AC current flows through this coil, it generates a magnetic field within the transformer's core. The intensity of this magnetic field is directly proportional to the current passing through the coil. Transformer winding is usually made from copper due to its low resistance and good conductivity.

The iron core of the transformer is often constructed from materials with high magnetic permeability, such as iron. This core serves a critical role in efficiently directing and intensifying the magnetic field generated by the primary coil. Without the core, the transformer's efficiency would be severely compromised.

*See below for more details.

The secondary coil, featuring fewer turns than the primary coil, is connected to the load or the device you want to power. As the magnetic field generated by the primary coil passes through the secondary coil, it induces an electromotive force (EMF), leading to the generation of AC voltage suitable for the load. The ratio of turns between the primary and secondary coils determines the voltage reduction or 'step-down' effect.

Both coils are wound around the same core material to produce the most efficient magnetic coupling.

The primary purpose of a step-down transformer is to reduce the input voltage (or primary voltage) to a level suitable for the connected load. The turn ratio between the primary and secondary coils directly influences the amount of voltage reduction. Essentially, as voltage is 'stepped down,' the current is proportionally increased, maintaining the conservation of power.

The output voltage (or secondary voltage) of the step-down transformer can be calculated by dividing the number of turns on the secondary windings by those on the primary, then multiplying this by the primary voltage.

By adjusting the number of turns in each coil and their relative positions, you can precisely control the secondary voltage rating to match the requirements of your electrical equipment.

Without this physical law relating to electromagnetic induction, a step-down transformer wouldn't work.

This law tells us that when you have a coil of wire, like the ones in a step-down transformer, and you change the amount of electrical force (voltage) flowing through one coil, it creates a change in the magnetic field around it.

In a step-down transformer:

So, thanks to Faraday's Law, the changing magnetic field between the two coils allows the step-down transformer to reduce the voltage on the secondary side. It's a bit like a relay system – changing something on one side causes a change on the other side, but the magic happens through the invisible magnetic connection between the coils.

The core of a transformer is a crucial component that plays a central role in its operation, involving the concept of magnetic flux. Let's explain this in a straightforward manner:

So, in simple terms, the core of a transformer is like a pathway for the invisible energy flow, or magnetic flux, created when electricity flows through it. It guides this energy to where it's needed and prevents it from going to waste. This allows the transformer to do its job, which is to adjust the voltage or electrical force to a level suitable for different applications.

H and X terminals, commonly found on certain step-down transformers, serve important purposes in transformer installations, and these were established by the electric power industry to avoid confusion. Let's explain their roles in simple terms:

H Terminal (High Voltage Terminal):

X Terminal (Common or Ground Terminal):

In summary, the H terminal is where high voltage enters the transformer, while the X terminal is a common or ground point that might have other specific functions in the electrical circuit. These terminals are vital for proper transformer operation and ensuring that electrical connections are safe and reliable.

The transformation ratio is equal to the square root of the primary to secondary inductance. It can be a challenge to get your head around if you're not used to this kind of thing!

Think of a step-down transformer as a device that adjusts the strength of an electrical force, which we measure as voltage. It has two sides, one where the voltage is high (the primary side) and the other where the voltage is low (the secondary side).

Now, the voltage ratio in a step-down transformer is like a recipe that tells us how to adjust this powerful river into a manageable stream. If the recipe says 10:1, it means for every 10 units of force on the primary side, the transformer reduces it to 1 unit on the secondary side.

So, when you see a voltage ratio, it's like a set of instructions for making the force more suitable for your needs. It helps ensure that the devices we want to power receive the right amount of electrical force – not too strong, not too weak, just right.

In simple terms, a step-down transformer is like a voltage-adjusting tool that takes a strong electrical force and makes it weaker, and the voltage ratio between primary and secondary voltages is like the recipe that guides this adjustment. It ensures that the electricity provided is just right for our devices to work safely and effectively.

In this context, primary and secondary windings are essential components that play distinct roles in the transformation of electrical voltage. These windings are coils of wire wrapped around the transformer's core, and they are responsible for transferring electrical energy from the input side (primary winding) to the output side (secondary winding). Let's explore these two windings in more detail:

In summary, the primary winding of a step-down transformer is where the high-voltage input is received and used to generate a magnetic field. The secondary winding is where the transformed voltage is delivered to power the connected load.

By carefully adjusting the number of turns on these windings and the design of the transformer's core, step-down transformers efficiently and effectively regulate voltage for various applications, ensuring the safe and optimal operation of electrical equipment.

We are often asked, can you reverse-feed (or back-feed) a transformer operation?

While some sources claim that it is okay to do this, in principle, we would not recommend this for the following reasons:

When you reverse-feed a step-down transformer, you essentially use it in a way that it wasn't designed for. This is an inefficient method because of the relationship between voltage and current. Letting the primary winding power a load could be asking for trouble.

A step-down transformer is meant to take in high voltage and reduce it to a lower voltage for safe and efficient use.

However, when you reverse-feed it, you do the opposite. You provide a lower voltage as the input, which the transformer then tries to reduce even further. This can lead to some unintended consequences:

In simple terms, reversing a step-down transformer is like trying to use a device in a way it wasn't meant for. It can lead to unexpected and potentially harmful outcomes, including higher voltages and potential damage to the transformer and connected equipment. Essentially, you will be unable to adjust the primary voltage rating to account for minor fluctuations in supply voltage.

Because of this, a variance of more than 5% will result in energy loss and overheating.

It's always important to use electrical equipment as intended to ensure safety and proper operation.

A step-down transformer's primary application is to reduce voltage levels for the safe and efficient operation of electrical equipment, ensuring compatibility with the device's voltage requirements. It is used in various sectors, from industrial settings to households, where different voltage standards or the need for voltage reduction and safety are critical.

Yes, they are known for their energy efficiency. By adapting the voltage to match the requirements of the connected load, they minimize energy wastage. This results in cost savings on utility bills and contributes to a more environmentally friendly operation.

Safety should always be a top priority when using electrical equipment. Here are some key safety precautions:

While step-down transformers are versatile and can be used with a wide range of equipment, not all devices are compatible with them. Some equipment, such as those with high-frequency components or motors, may not work optimally with a step-down transformer. Consult the equipment's documentation or an electrical professional to determine compatibility.

Selecting the right step-down transformer involves considering several factors:

It's advisable to consult with an electrical professional to ensure that you choose the correct transformer for your specific requirements.

While many step-down transformers are designed for indoor use, there are models specifically made for outdoor applications. If you plan to use a step-down transformer outdoors, ensure that you select a transformer rated for outdoor use. This ensures that it can withstand exposure to the elements and maintain safe and efficient operation.

Yes, step-down transformers, like many electrical devices, should undergo periodic maintenance to ensure their continued reliability and safety. Maintenance tasks may include:

Regular maintenance helps extend the lifespan of the transformer and reduces the risk of unexpected failures.

The noise level of a step-down transformer can vary depending on several factors, including its design, size, and cooling mechanisms. Generally, larger transformers and those with more complex cooling systems may produce more noise. If noise is a concern, you can seek out step-down transformers specifically designed for quiet operation.

Yes, step-down transformers can be seamlessly integrated into renewable energy systems to adapt the voltage for grid connection or power appliances. This is especially useful when the voltage generated by renewable energy sources, such as solar panels or wind turbines, does not match the standard household voltage. Step-down transformers allow for a smooth transition, ensuring your renewable energy source effectively powers your home or facility.

In conclusion, step-down transformers are invaluable devices that play a crucial role in ensuring safety, compatibility, and energy efficiency in electrical systems. Whether you need to power sensitive electronic equipment, make imported appliances functional, or enhance the stability of your industrial machinery, step-down transformers have a place in various applications.

At Powervolt Team, we understand the significance of these transformers in your everyday life. We hope this comprehensive guide has provided you with a thorough understanding of what step-down transformers are, their benefits, and how they function. If you have any more questions or need assistance in choosing the right step-down transformer for your specific needs, don't hesitate to contact us. We're here to empower you with electrical solutions that make your life easier, safer, and more efficient.