Need a grant for LED upgrades or

voltage optimisation? (read more)

Need a grant for LED upgrades or

voltage optimisation? (read more)

In the complex landscape of electrical systems, a term that often crops up is "Power Factor Correction." Understanding its significance is crucial, especially when it comes to the efficient use of electricity. This blog will examine this subject to discover what it is, how it functions, its benefits, and why it is an absolute necessity for your business or industrial setup.

Power factor (PF) is a fundamental parameter in electrical systems, representing the ratio of real power (measured in kilowatts, kW) to apparent power (measured in kilovolt-amperes, kVA). In simpler terms, it quantifies how efficiently electrical power is converted into useful work.

Ideally, all the power drawn through the AC power supplies should be useful power, but this only works when the voltage is in phase with the current.

A power factor of 1 (or 100%) denotes perfect efficiency, where all the supplied electrical power serves a purpose. However, real-world scenarios are rarely so ideal; electrical systems often exhibit a power factor of less than 1 for a variety of reasons, primarily inductive loads like motors and transformers, causing the current to lag behind the voltage. This lag leads to a lower PF and, consequently, a drop in energy efficiency.

Power factor correction is the process of optimising the power factor in an electrical system. It involves the installation of specialised equipment designed to counteract the reactive power (expressed in kilovolt-amperes reactive, kVAr) caused by inductive loads, thereby raising the power factor closer to 1. When you improve the power factor, you improve the quality of the power supply.

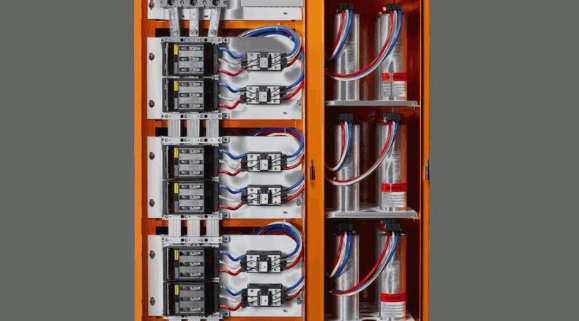

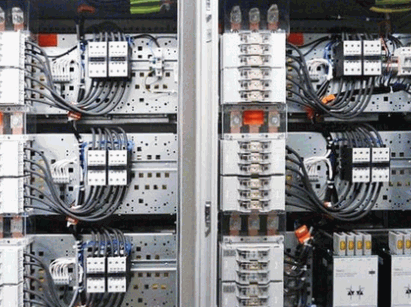

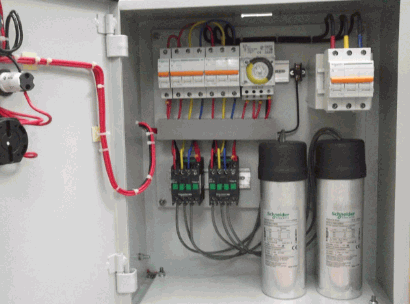

Power factor correction is achieved by employing power factor correction devices, specifically capacitors for passive PFC and more advanced active power factor correction (APFC) systems. These devices are typically installed on your electrical distribution system to counteract the negative efficiency of electric motors or machines.

Let's find out how these devices function:

APFC systems continuously monitor the power factor and dynamically adjust the phase of the current supplied to the load using a power factor controller. This technology works by injecting a leading or lagging power factor to align with the voltage, effectively correcting the power factor to unity (1). APFC is highly accurate and responsive to varying load conditions, making it a preferred choice in many applications.

Passive PFC predominantly involves capacitors. When connected to the electrical system, capacitors store and release electrical energy in response to voltage and current fluctuations. These capacitors supply reactive power that compensates for the lagging current due to inductive loads, subsequently elevating the power factor. While it is less sophisticated than APFC, passive PFC is still effective and commonly used in numerous settings.

Power factor correction devices are typically installed at the point of common coupling, where electricity is supplied to a facility or a specific electrical load. They continually monitor the power factor, automatically adjusting their operation to maintain it at an optimal level.

The power triangle is a graphical representation of the relationship between real power (in watts, W), reactive power (in volt-amperes reactive, VAR), and apparent power (in volt-amperes, VA) in an electrical circuit. It is often used to illustrate the concept of PF. In the power triangle, real power is represented as the horizontal component, reactive power as the vertical component, and apparent power as the hypotenuse of a right-angled triangle. The PF, which is the cosine of the angle between the real and apparent power vectors, quantifies the efficiency of power usage in an electrical system. A higher PF indicates that a larger portion of the supplied power is being used for useful work, while a lower PF suggests that a significant portion is lost as reactive power.

Now that we've established what PFC is and how it functions, let's explore why it is indispensable and why businesses and industries should give it their utmost attention.

The primary reason for implementing PFC is to enhance energy efficiency. A poor power factor results in increased energy consumption because a substantial portion of supplied electrical power is squandered as reactive power. By elevating the PF, you can significantly reduce electricity bills and, importantly, reduce your carbon footprint. Because this reduces voltage drop at the conductor, the voltage to the equipment is increased, making it run more efficiently.

An improved power factor means you're billed only for the real power utilised for productive work, not the reactive power. This translates to lower energy costs, as you cease to be charged for the wasted reactive power. For example, an uncorrected electrical load may consume 20% more power.

PFC stabilises and improves voltage stability within your electrical system. Voltage fluctuations can cause equipment damage and malfunctions. By maintaining a high power factor, you ensure a stable and reliable power supply, reducing the risk of voltage-related issues.

PFC can free up additional capacity in your electrical system. When the power factor is low, a substantial portion of the electrical capacity is consumed by reactive power. By correcting the power factor, you make more efficient use of your existing infrastructure without requiring costly upgrades.

Some regions have regulations and standards in place, requiring businesses to maintain a specific power factor. Non-compliance can lead to penalties or higher tariffs.

A high power factor results in less stress on electrical equipment, reducing the risk of overheating or voltage-related damage. This, in turn, extends the lifespan of your machinery, reducing maintenance costs and downtime.

PFC enhances power quality by minimising voltage drops, power loss and fluctuations. The device measures input voltage and makes sure it is in phase with the current. This leads to a more reliable power supply, reducing the likelihood of disruptions in your operations.

By reducing energy wastage and lowering your carbon footprint, PFC contributes to a greener and more sustainable approach to energy consumption. This isn't just beneficial for your business but also for the environment, aligning with responsible corporate practices.

Conversely, neglecting PFC can have adverse consequences, including:

To explain this further, imagine a large manufacturing facility that uses a substantial amount of electrical power to operate its machinery. The facility's overall power factor is 0.7, which is below the recommended ideal of 1, known as the unity power factor. This means that the electrical system in the facility is not using power efficiently, and a significant portion of the electricity supplied is being wasted.

Here's what could happen in this scenario:

In summary, if an electrical load operates at a power factor of below 0.8, it can lead to increased electricity costs, voltage instability, reduced system capacity, potential penalties, and a negative environmental impact. Power factor Correction becomes crucial in such scenarios to improve efficiency, reduce costs, and ensure the stable and reliable operation of electrical systems.

Understanding the impact of Power Factor Correction on current and AC voltage waveforms is crucial. Without PFC, the current waveform can exhibit significant harmonic distortions and phase shift due to reactive power. These distortions can lead to inefficient operation, voltage instability, and increased heat in the system, potentially damaging sensitive equipment. PFC helps to align current and voltage waveforms, reducing harmonic distortions and ensuring a smoother and more efficient flow of electrical energy.

Voltage optimisation is all about making sure the voltage in your electrical system is just right, like adjusting the heat on your stove. Now, it's easy to confuse Power Factor Correction with Voltage Optimisation, so let's take a moment to explain the differences.

Voltage is like the pressure of the electricity flowing through your system. Sometimes it can be too high, like a pressure cooker with too much steam, or too low, like a stove that's not hot enough. Voltage optimisation makes sure it's just right.

Uncover more: What Is Voltage Optimisation?

Voltage optimisation uses devices called voltage stabilisers or regulators. These devices keep a close watch on the voltage coming into your system and make real-time adjustments to keep it steady.

Delve further: When Does Voltage Optimization Not Work?

Having the right voltage is crucial for your equipment and operations. Here's why it's important:

Now that we understand Power Factor Correction and voltage optimisation, let's look at the key differences between them:

Goal

Focus

Devices Used

Benefits

Applications

So, Power Factor Correction and voltage optimisation are both essential for different aspects of your electrical system's performance. They work together to make sure your electricity use is efficient and safe. If you need help with either of these solutions, you can always reach out to experts like Powervolt Team. They'll make sure your electrical system is running at its best, whether you're at home or work.

Remember, using electricity wisely and safely benefits not only your budget but also the environment, and it keeps your equipment working smoothly. It's a win-win for everyone!

Delve into: What Is The Difference Between Voltage Optimisation And Power Factor Correction?

What is the distinction between real power and apparent power (or active and reactive power)?

Real power (in kW) represents the actual power used for productive work, while apparent power (in kVA) is the combination of real power and reactive power. In essence, real power is the useful energy, while apparent power accounts for the total energy, both useful and reactive.

What is reactive power, and why does it impact the power factor?

Reactive power (kVAr) is the power that oscillates between the source and the load due to inductive or capacitive elements. It doesn't perform any useful work but circulates in the electrical system. It affects the power factor because it causes the current to lag (inductive) or lead (capacitive) the voltage, resulting in an inefficient power factor. High levels of reactive power can strain the electrical infrastructure, reducing overall efficiency.

How can I ascertain the power factor of my electrical system?

To determine the power factor of your electrical system, you can use a power quality analyser or check your utility company's bill. Utility bills often include information about power factors. A power quality analyser provides a more detailed and real-time measurement of the power factor, helping you identify areas for improvement.

Is power factor correction only relevant to industrial and commercial settings?

While PFC is more commonly implemented in industrial and commercial settings, it can also be beneficial in residential applications, particularly when significant inductive loads are present. It can lead to energy savings, reduced utility bills, and a more stable electrical supply.

Are there any risks associated with power factor correction?

When PFC devices are not properly configured or maintained, they can overcompensate, leading to a leading power factor, which may affect the performance of equipment and systems. Overcorrection can result in voltage instability, overheating, and reduced equipment lifespan. It's essential to consult with experts to ensure the correct installation and ongoing maintenance of PFC equipment.

How frequently should power factor correction systems be inspected and maintained?

The frequency of inspection and maintenance for PFC systems can vary based on specific equipment and usage. In most cases, it is recommended to perform inspections at least annually or semi-annually. Regular maintenance checks help ensure that the PFC devices are operating optimally, contributing to energy efficiency and system stability.

What role does the power factor play in utility bills?

Power factor plays a crucial role in determining the charges on your electricity bill. A low power factor can result in penalties or higher tariffs from utility providers. Utilities often charge more for customers with inefficient power factors as it places a strain on their distribution systems. By improving your power factor, you can reduce these additional charges and lower your energy costs.

Can power factor correction devices help reduce carbon emissions?

Yes, PFC devices can play a role in reducing carbon emissions. By improving energy efficiency and reducing energy wastage, PFC contributes to a lower carbon footprint. This aligns with sustainability and environmental conservation efforts, making PFC a responsible choice for businesses and individuals seeking to reduce their environmental impact.

What is the role of capacitors in passive power factor correction?

Capacitors are integral to passive PFC. These capacitor banks store and release electrical energy to offset the lagging current caused by inductive loads. By providing reactive power in the form of leading current, capacitors help raise the power factor, resulting in increased efficiency in the circuit current. Passive PFC using capacitors is a common and cost-effective method for improving power factor in many applications.

How do active Active PFC systems differ from passive PFC?

Active PFC and passive PFC differ in their operational principles and adaptability. APFC systems are dynamic and continuously monitor the power factor, making real-time adjustments. They inject leading or lagging currents as needed to maintain a high and stable power factor, usually close to unity (1). Passive PFC primarily involves capacitors, which provide a fixed amount of reactive power correction. While passive correction is simpler and less dynamic, APFC systems are highly adaptable and suitable for applications with varying load conditions, ensuring precise PFC in real-time.

In conclusion, power factor correction is a fundamental aspect of electrical systems that significantly impact energy efficiency, cost savings, equipment lifespan, and environmental responsibility. By optimising your power factor through the use of correction devices, you can enhance the performance of your electrical infrastructure and contribute to a sustainable future. Whether you are in an industrial, commercial, or residential setting, power factor correction is an investment in a more efficient and eco-friendly approach to electricity consumption. For tailored PFC solutions, consult Powervolt Team to embark on your journey towards improved energy efficiency and a greener future.

We hope this blog has illustrated the importance of power factor correction in the realm of electrical engineering and energy management. However, if you have any further questions, Powervolt Team is here, as always, to guide you.